Category

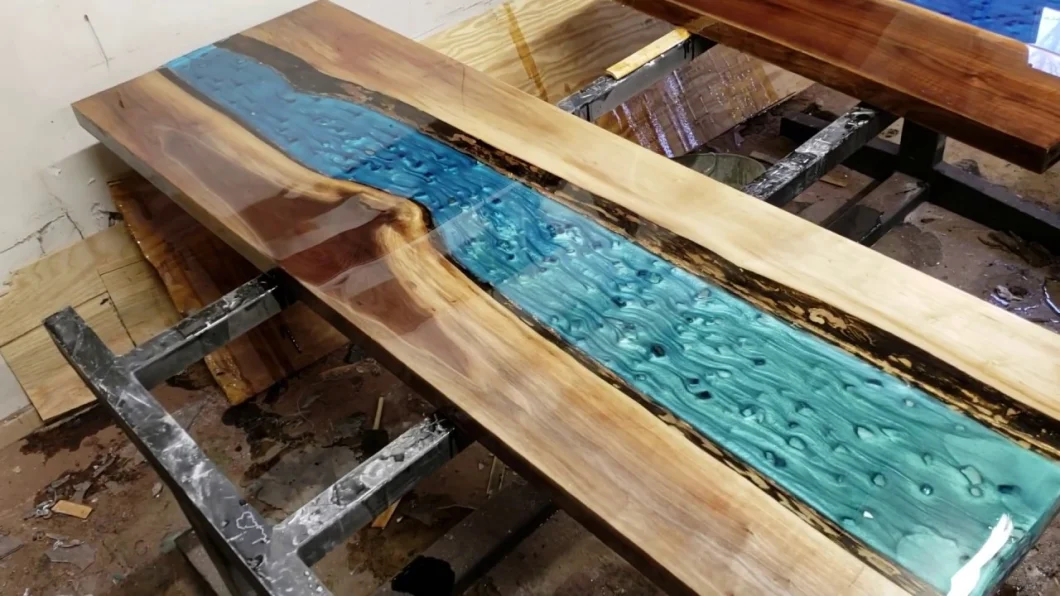

Professional Vendor OEM ODM No Bubbles Ab Glue Natural Defoaming Adhesive Casting Epoxy Resin for River Table

Overview Professional Vendor OEM ODM No Ripple AB Glue Natural Defoaming Adhesive Clear Epoxy Resin For Wood River Table

Overview

Professional Vendor OEM ODM No Ripple AB Glue Natural Defoaming Adhesive Clear Epoxy Resin For Wood River Table

FeatureEpoxy resin HF402 can be cured under normal temperature and elevated temperature, with good flowing property, natural defoaming, high hardness, no ripple, bright in surface.

Free samples are available! Please contact us for more details and tell us what you need!

Basic Info.

| Model NO. | HF402 |

| Bonding Function | Pressure sensitive Adhesive |

| Morphology | Water-Soluble |

| Application | Construction, Woodworking |

| Material | Epoxy |

| Classification | Room Curing |

| Main Agent Composition | Natural Polymer |

| Characteristic | Waterproof |

| Promoter Composition | Curing Agent |

| Composition | Organic Material |

| Color | Clear |

| Ripple | No Ripple |

| Voc | Low Voc Low Odor |

| UV | UV Resistant |

| Solids | 100% Solids |

| Leveling | Self-Leveling and Extremely Durable |

| Certificate | RoHS,Reach, PAHs, ASTM |

| Type | Two Components Epoxy Resin Glue |

| Transport Package | Bottle/ Barrel |

| Specification | 1KG/5KG/20KG/50KG/ 200KG |

| Trademark | HF |

| Origin | Guangdong |

| HS Code | 3506912000 |

| Production Capacity | 5000000 Tons/Year |

Product Description

Professional Vendor OEM ODM No Ripple AB Glue Natural Defoaming Adhesive Clear Epoxy Resin For Wood River Table

Product Parameters

| Item (HF402) | Epoxy Resin(A ) | Epoxy Resin(B ) |

| Color | Transparent Liquid | Transparent Liquid |

| [email protected]ºC(mpa.s) | 380-450 | 30-40 |

| Mix Ratio(by weight) | 2 | 1 |

| Hardness(Shored) | 75-80 | |

| Operation time(100g mixed glue ,25ºC) | 50-60minutes | |

| Curing Time(25ºC) | 24-26hours | |

| Curing Time(35ºC) | 8hours | |

| Curing Time(25ºC) | 6-12months | |

FeatureEpoxy resin HF402 can be cured under normal temperature and elevated temperature, with good flowing property, natural defoaming, high hardness, no ripple, bright in surface.

* No Toxic Organic Compounds or Heavy Metals

* 100% Solids, Low VOC, Low odor,UV resistant

* Self-Leveling and Extremely Durable

* Crystal Clear, High Gloss and Excellent Color Stability

*Not whitish, no bubbles

*Anti-yellow for at least five years

*Food grade resin

Detailed Photos

More Applications

Free samples are available! Please contact us for more details and tell us what you need!

Packaging & Shipping

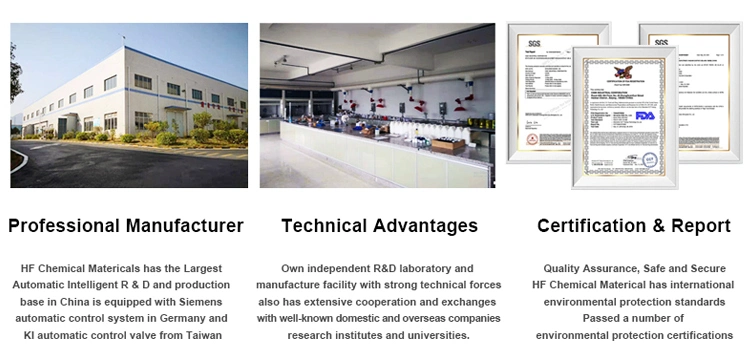

Our Advantages

Free samples are available! Please contact us for more details and tell us what you need!

Customers Feedback